Leather is one of the most durable covers in upholstery. Confusion often lies in the different types of leather. As we learned in Lesson Two, Raw Material, the corium layer is what gives leather the strength for durability. The finish is what separates leather types. Here we will highlight the unique and distinctive characteristics of all types of leather and what sets them apart.

Once hides have been processed, they are a stable leather material and move onto the Finishing Operations. Finishing is a fine art in that any desired effect can be created during these steps. Deciding the look and end use application for a leather article, the technical team at a tannery builds a “finish” or a series of steps to process leather into a desired look. The requirements for leather are different depending on the use of leather.

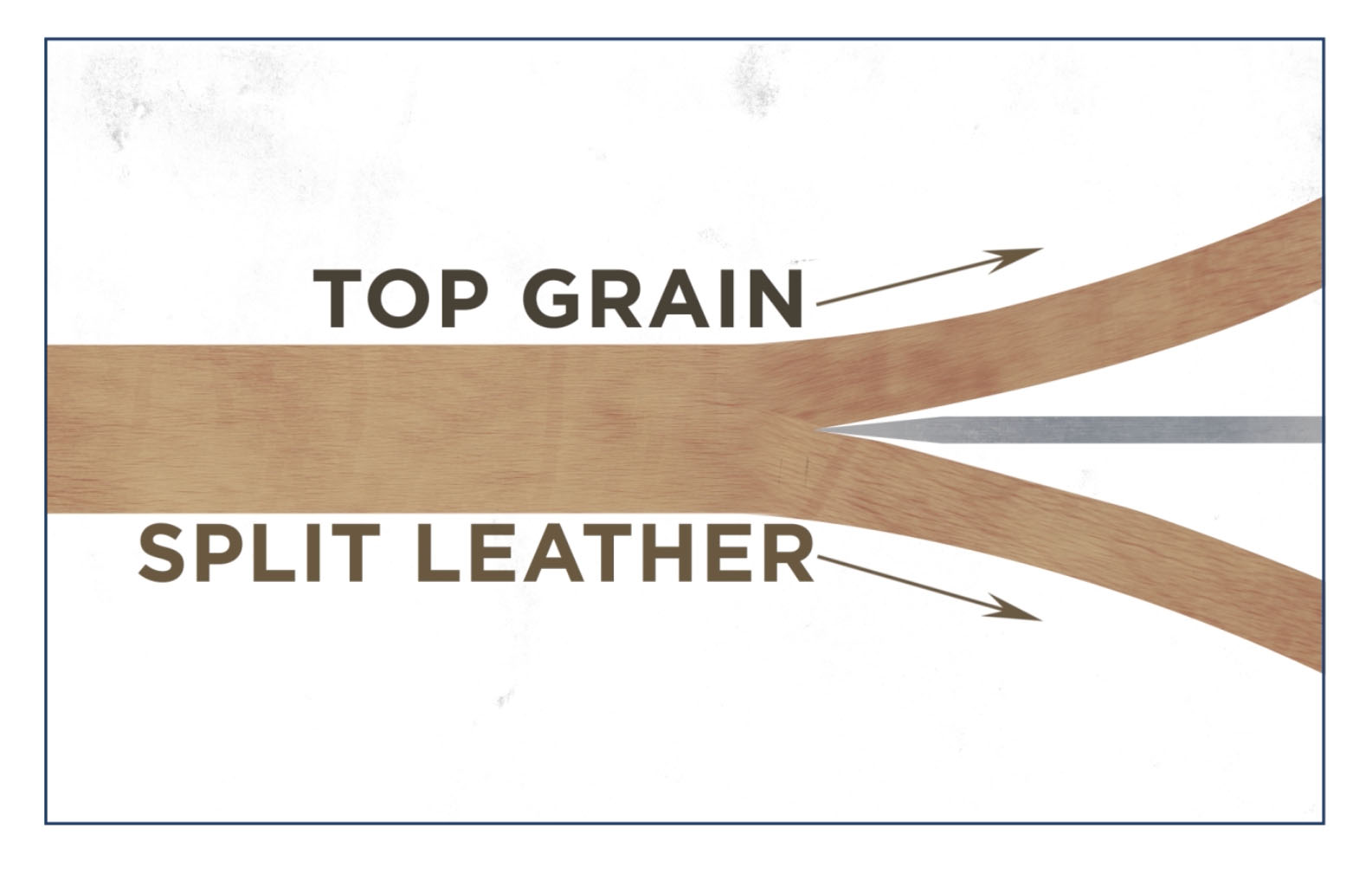

Leather is split into layers and sold as different products:

Top Grain is the uppermost portion of a hide. The split layer is the bottom layer. Splits are often produced as suede, but can be finished into smooth leather. From the Top Grain layer, Full Grain, Pigmented and Corrected Grain originate.

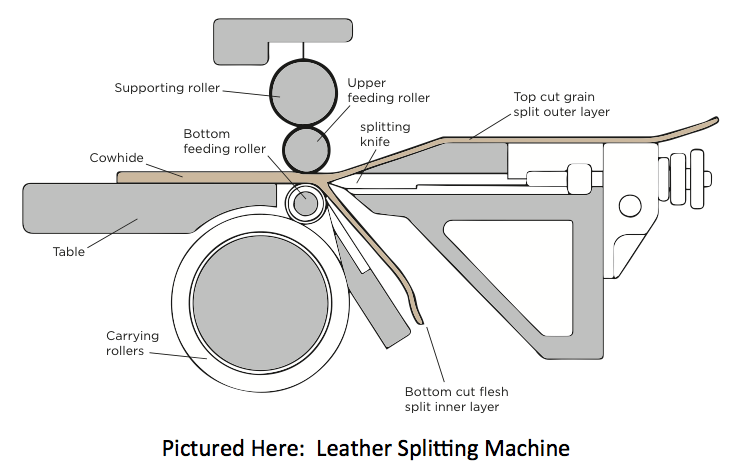

This operation takes place on a splitting machine where the layers are separated as pictured below.

Top Grain leathers are products of the uppermost layer of the hide. Top Grain strictly refers to the location of the hide from which the leather is produced. It is often confused with corrected grain.

Full Grain leathers are top grain leathers, unaltered by sanding or buffing or any other treatment. The grain layer remains intact, retaining the original texture and markings that naturally occur during the lifetime of the animal. The finest leather goods are made of full grain leather, as only the best hides are utilized. Natural grain will develop a patina over time. Patina is the word used to describe the effect of wear and use on natural leather. It often darkens the surface of leather over time and is a hallmark of the finest of leathers. Other organic materials patina such as wood and metal.

Split refers to leather made from the lower layer of a hide that has been split away from the top grain. Splits are often produced into suede, but can also be finished into smooth leather.

Suede is a split leather that has been buffed to create a soft, fuzzy surface. It is produced from the inner layer of a hide.

Nubuck is the result of buffing and brushing the grain layer of a hide in order to achieve the velvety drag and soft surface feel. This surface feel is also referred to as hand-feel.

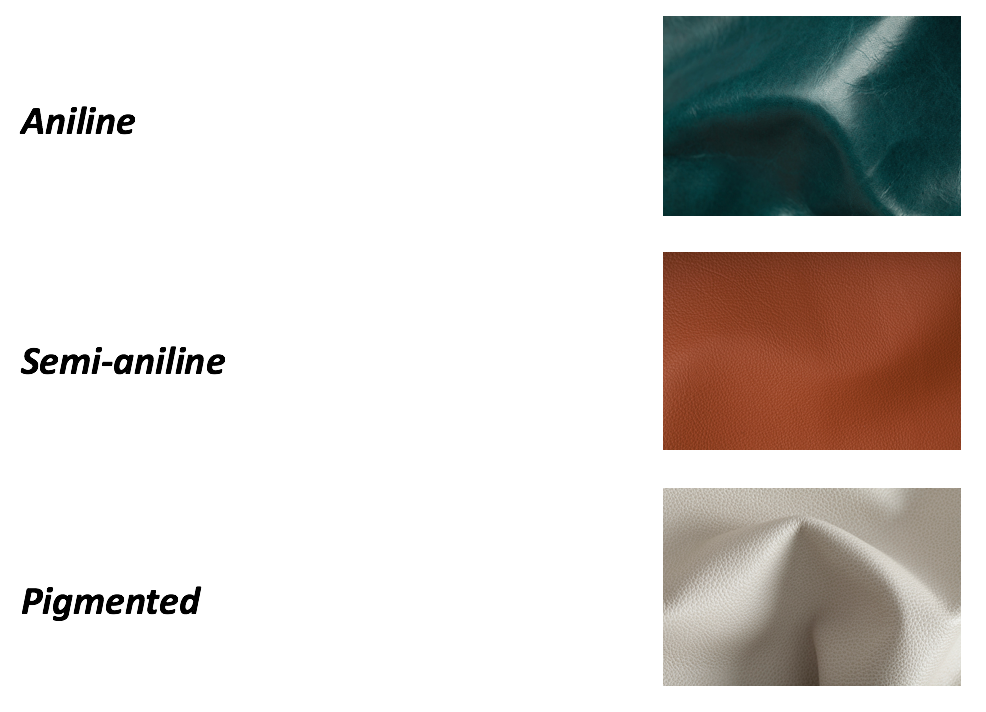

There are a variety of leather looks that can be achieved through finish applications, but there are usually 3 categories that leather falls into:

In achieving these different types of desired effects and ranges of there are a variety of process steps.

Aniline leather has been colored by immersing hides in a dye bath of transparent, aniline dyes. These leathers are the most natural and often the most pristine hides are used. All natural markings (or beauty marks) will be visible in aniline dyed leathers.

Semi-aniline leather is produced in a similar method to aniline dyed leather in that it is fully dyed through, but has a light surface coating and small amount of pigment in the base coat. It retains a natural appearance with beauty marks still visible to the naked eye. The surface coating helps to create increased stain resistance.

Pigmented leather is less natural in appearance and has a polymer coating on its surface. It is also referred to as full finish leather. The polymer coating contains pigment that serves as a protective coating on the hide’s surface. Natural characteristics of the hide are not visible with this application. These leathers often have greater wear resistance, water resistance and protection from staining.

Corrected Grain is top grain leather that has had its surface grain sanded or buffed to remove imperfections on the surface. A polymer coating with pigment is applied for achieving uniform color and consistency.

Hair on Hide is leather that has been tanned with the hair in-tact.

Embossed leather has been “stamped” under extreme heat and pressure with a pattern or print to add character.

Patina is an effect produced by the contact of oil and natural wear on a full grain leather. It is the hallmark of a natural leather and considered the aesthetically pleasing by many.

Pull-Up is a characteristic achieved through wax/oil blend finishing. Pull up is showcased when leather is pulled taut over a furniture frame or a shoe last. There is a marked difference in color between the base color and the top color.

Patent Leather was invented in the late 1700’s in England. It was later brought to the United States in the early 1800s. Characterized by a mirror like finish, patent leather is shiny and glossy, most notably popular in the color black. It has been used in formal dress footwear and dance shoes.