In leather tanning, like in fine cooking, ingredients play a key role. Raw materials and the tanning processes from different regions of the world are important to the makeup, hand, texture and natural characteristics of each leather. A direct by-product of the meat industry, meaning that animals are primarily raised and slaughtered for their meat, hides have been and continue to be a long-lasting, functional and sustainable product. Versatile in both function and design, these raw materials would otherwise have to be disposed of through a tedious burning process or occupy space in landfills.

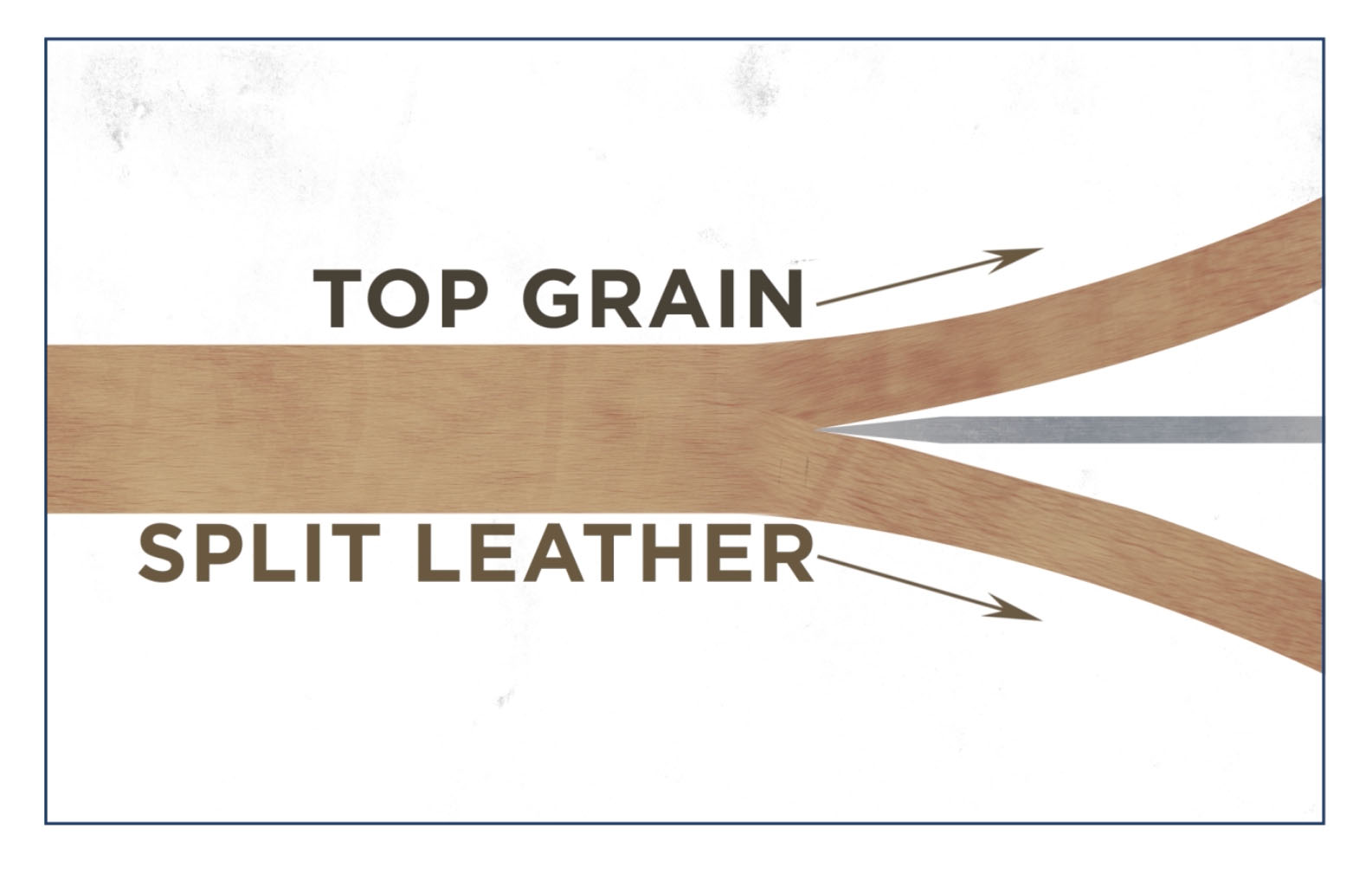

Leather is split into layers and sold as different products:

Leather is produced from the skin or hide of an animal, a by-product of the meat and dairy industries.

Hides and skins differ in their grain structure, age, sex and breeding of an animal and are the raw material for leather. A hide refers to the skin of a large, full-grown animal such as bovine, or cattle. Skin is the term used for describing small animals such as calves, sheep, pig and goats.

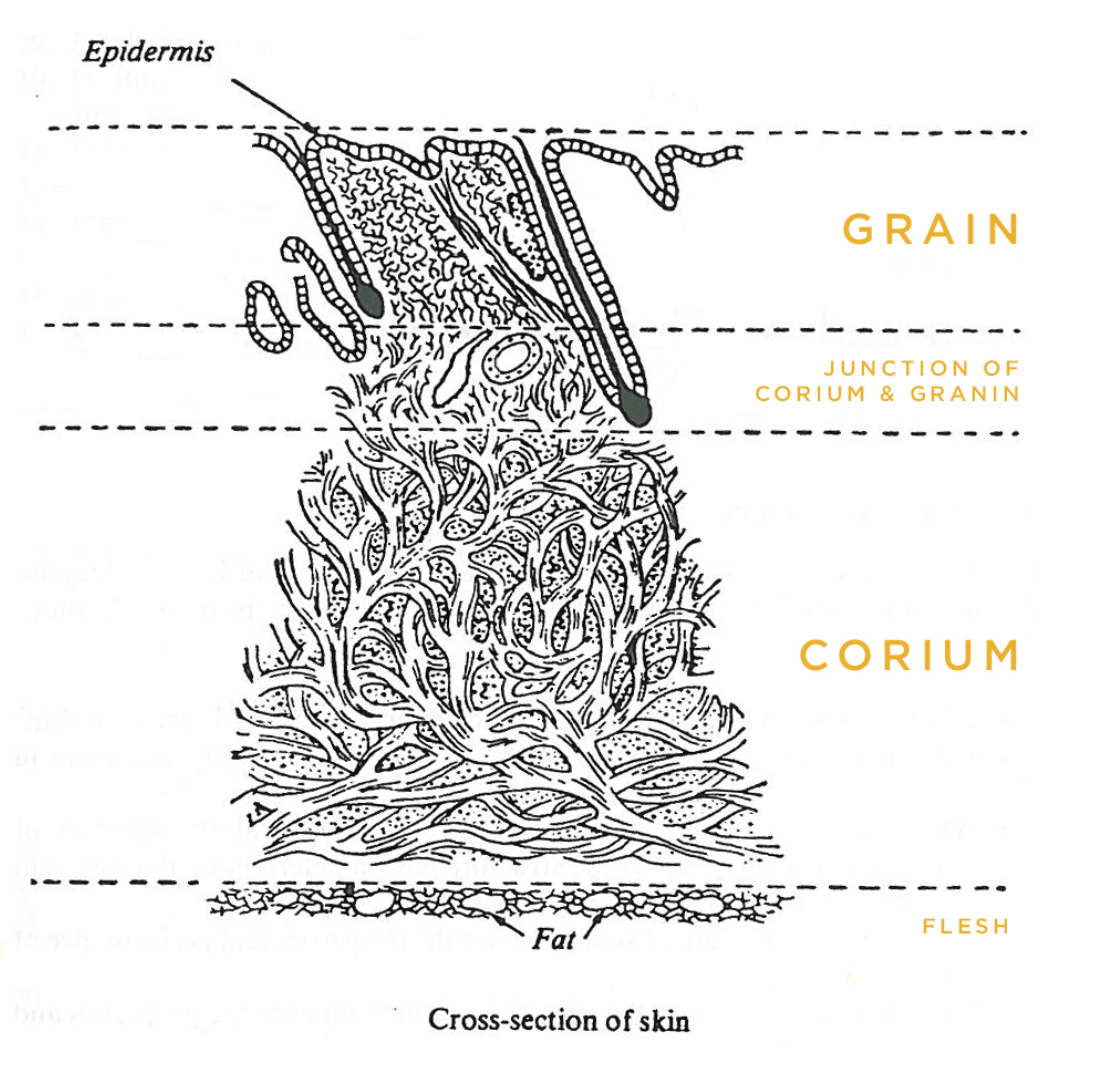

It is important to remember that the hide is the skin of an animal and what protects the animal from its environment. Skin has a complex structure and is anisotropic, meaning its structure varies in thickness over its area. Collagen is the structural protein that makes up skin structure.

It is the most abundant protein in mammal bodies. The epidermis is the outermost layer of the raw skin and what separates the animal and its environment. During the hair removal stage of leather processing, the epidermis is removed. The uppermost layer of skin is what is referred to as grain. The grain layer is the most valuable part of the skin in that it is "in-tact" and not altered and will provide the appearance of grain. Corium is the fibrous structure of the skin below the grain layer. Here, the weave of collagen fibers is described as a random entanglement making the corium (and leather) exceptionally strong.

Upon receipt at the tannery, hides can be as thick as 10 mm, or 1 centimeter. At this thickness, the hide is too thick for upholstery use.

Splitting is an operation carried out on a "splitting" machine. In this operation, the top grain portion of a hide is separated from the bottom portion. The top grain portion is the strongest layer and is produced into Full Grain and Top Grain leathers. The bottom layer is referred to as the split layer. It is not as strong, but has its purposes. Split leather is often produced into suede.

Shaving is later performed to exact weights as close to the finish weight as possible.

Leather is sold at different grades. Grade refers to quality. The quality is determined by the grain surface of the hide. Environment, climate, feed type and husbandry all have a direct correlation to the natural characteristics you will find within a hide. Brands, manure damage, parasitic damage, scars and scratches are all inherent in the nature of this raw material. Good hides or good grades produce a greater cutting area or yield.

These hides are coveted as the best hides because they are scarce. Insect bites, parasitic damage, scratches and other natural markings are a testament to the authenticity of leather, but can prove to be difficult to cut around in some hides. Husbandry, or how an animal is treated as it is raised accounts for some of the nature of the material. Some cattle are free from barbed wire fencing while other cattle live within those fences their entire lives. Brands are a common trade practice on cattle ranches and are a way of identifying the herd.

Some ranchers use ear tags instead, but these practices are at the discretion of the rancher and are not required. Brazilian cattle are known for their brands, where German cows are often ear tagged instead. We will discuss finish applications in later modules that help with masking some of the hallmarks of the trail.

There are 800 breeds of cattle recognized worldwide. Cattle are raised for milk, meat and for use as draft animals. Originally domesticated 8,500 years ago in Europe and the Middle East, cattle has been roaming the earth for hundreds of thousands of years. Cattle was imported into the US in 1623 from Europe.

The gestation period (pregnancy) lasts 9 months. At birth, calves weigh between 55-99 pounds. When full grown, depending on the breed, cattle can weigh up to 2,000 pounds.

Based on a 2010 United Nations report on world hides and skins numbers, at the time the world had approximately 1.6 billion head of cattle.

Asia - 690 million. India is the world's largest cattle producing country, producing over 324 million head of cattle each year. They produce cattle primarily for dairy, not beef. India is known for water buffalo, a bovine animal indigenous to South Asia, Southeast Asia and China.

Latin America - 408 million head of cattle.

Africa - 295 million head of cattle.

Brazil - 218 million head of cattle.

European Union - 121 million head head of cattle.

United States of America - 100 million head head of cattle. The US produces 25% of the world's beef.

Australia and New Zealand - 40 million head of cattle.

Cattle hides originate from both meat and dairy cattle. They are broken down into the below selections:

Cow: female, having calved at least once, 2-3 years old

Heifer: female, never has calved, under 3 years old

Bull: male, not neutered, 1-3 years old

Steer: male, neutered, generally 12-18 months old, but can be older

Cattle hides are versatile, used in the manufacture of furniture, automobile upholstery, aviation upholstery, footwear, ready to wear, small leather goods and more.

Dairy cows are often used in upholstery because of the size and grain. These hides tend to be large in size and softer in nature.

Bull and Steer hides are used where strength and durability are key as in footwear, shoe soles, belts and saddlery.

Calfskin: Dairy calves who have not been weaned from their mothers and are up to 1 year of age. Calfskin has a tight fiber structure, yet soft. It is used in the finest of leathers and for high quality furniture, clothing, shoes and wallets.

Sheepskin: Sheep are raised for their wool. Their skin serves as protection for the wool and not the animal. The wool protects the animal. For this reason, sheepskin is not known for its strength and durability. It is structurally open and has a loose fiber structure making it softer and exhibiting drape. Sheepskin (or lambskin) is primarily used in the manufacture of fine leather goods and soft goods.

Goatskin has a tight and unique fiber structure. It is a durable leather used in the manufacturing of footwear. Also known as kidskin, goat skin is used for gloves.

Pigskin is porous and has tough skin. It is primarily used as footwear lining, but can be used in footwear and handbags as well.

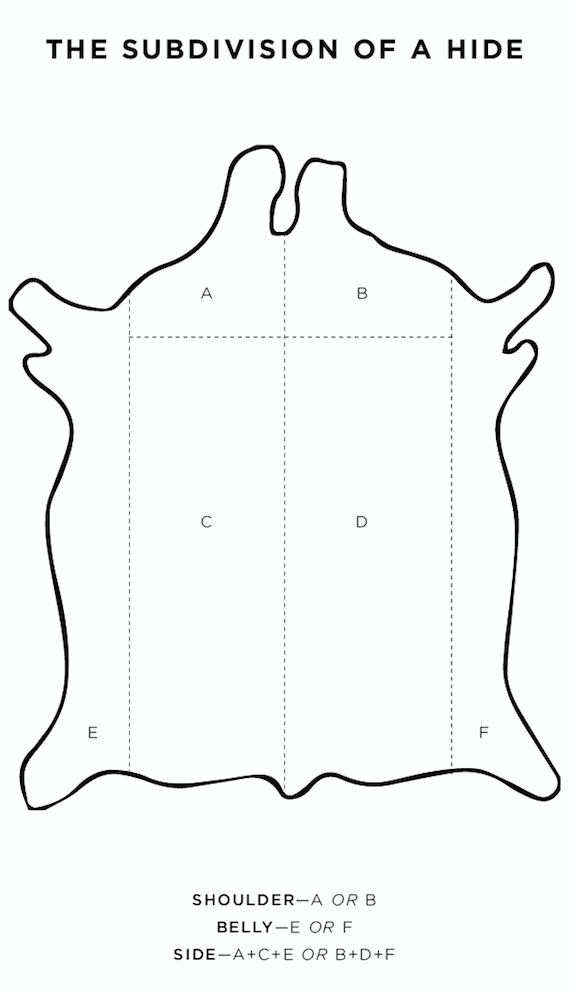

Hides are sold in a variety of configurations depending on the end use.

Whole Hide – The entire hide is utilized in this configuration. Furniture upholstery leather utilizes whole hides due to the size of patterns.

Side – A side is produced when a whole hide has been cut in half down the backbone. Footwear and small leather goods use leather in this configuration.

Shoulder – The area at the neck region is referred to as the shoulder. Belting leathers are sold in shoulder configurations.

Belly – This area of the hide has a looser fiber structure and is sometimes removed and sold off to other processing facilities before tanning. Bellies can be used to make rawhide for dog bones and gelatin for capsules, etc.

As soon as the hide has been removed at the abattoir, or slaughterhouse, the first step is preservation. Preservation is extremely important because it halts bacterial growth and the possibility of grain damage. Grain damage is often visible in a finished leather article unless a surface coating is added to mask it. There are several methods of preserving hides. The most common are Salt and Brine Curing.

Salt Curing is the most common method in Europe and North America. Approximately one pound of salt per pound of hide is used. Salt is applied by spreading over skins, then folding and stacking for storage. Salted hides will stay preserved in this state for up to a year if kept in a cool area.

Brine Curing takes less time. Using this method, hides are sent through a chilling machine and are then fleshed to remove excess fat and flesh. The remnants from this process are used in making soap. Fleshed hides are soaked in brine, a salt solution or bath, in vats or raceways for 48 hours until fully penetrated. Hides remain preserved for up to 6 months with this method.

Ice Packing Some tanneries utilize fresh hides, which can only occur when the raw material source is in close proximity to the tannery. Iced hides will remain fresh for up to 5 days. These hides are input into production upon receipt at the tannery.

Animal hides, the raw material of leather, have an overall impact on the final finished product. The size and grain character are only a few elements that will impact the look of a leather article. It is important to understand the origin of leather and the raw material when selecting a leather for a project.